Instructions to Page Editor Source from – get it from Lovejoy website

About Lovejoy, History & Acquisition by Timken

Since entering the power transmission marketplace in the 1920s, Lovejoy has emerged as an international market leader. Today, the Lovejoy brand is recognized around the world as the premier supplier of flexible shaft couplings and other power transmission components.

During the past century, Lovejoy has been a pioneer in advanced manufacturing technologies. Lovejoy created the industry-standard Jaw-style coupling in 1927 and was the first to incorporate rubber-in-compression as a power transmission concept. On 8 July 2016, The Timken Company, manufacturer of tapered roller bearings, announced its acquisition of Lovejoy, Inc. and its subsidiary, R+L Hydraulics GmbH.

Basic Information

Lovejoy is a global leader in couplings, power transmission, hydraulic components, and tension, and vibration management technology. More than 850000 combinations of bore sizes are available in the coupling.

Design Attributes & Advantages

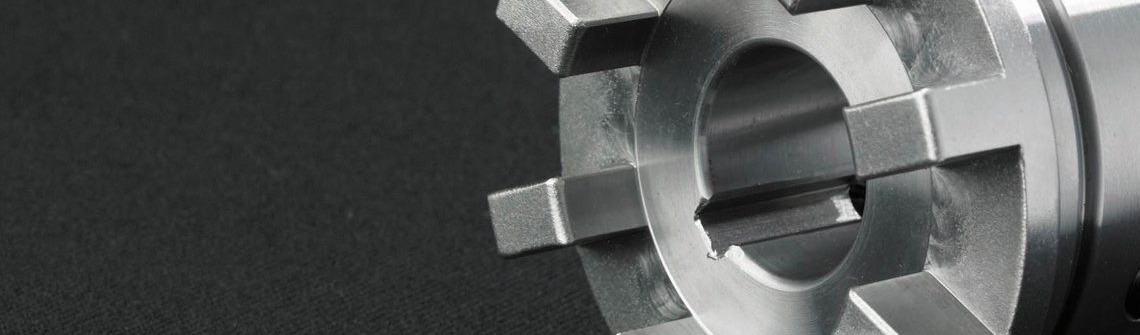

Jaw Coupling

The Jaw Type couplings from Lovejoy are offered in the industry’s largest variety of stock bore/keyway combinations. Lovejoy’s Jaw Type couplings are available in 24 sizes from a minimum torque rating of 3.5 in-lbs (0.4 Nm) to a maximum torque rating of 170,004 in-lbs (19209 Nm) and a bore range of .125 inches (4.45mm) to 7 inches (178mm).

- L type -standard jaw type coupling.

- Coupling offers standard shaft to shaft connection for general industrial duty application.

- Standard L-type coupling hub materials are either sintered iron or cast iron

- Resistant to oil, dirt, sand, moisture, and grease.

- Max. bore-2.875inches(73mm)

- Max. torque-12500 in-lbs(1412 Nm)

- AL type- Aluminium jaw coupling

- Light weight aluminium version of industry standard jaw coupling

- Accommodates for angular and parallel shaft misalignment.

- Max. bore- 1.875 inch (48mm)

- Max. torque- 2268 ln-lbs(256 Nm)

- SS type- Stainless steel jaw coupling

- Stainless steel version of industry standard jaw coupling

- Provides maximum protection against harsh environment.

- Max. bore-1.875 inches (48 mm)

- Max. torque-3708 in-lbs (419 Nm)

- SW type- radially removable elastomer

- Standard L type coupling with snap wrap elastomer and retaining ring

- 1750 RPM limit

- Max. Bore- 2.125 inches (55mm)

- LC type- radially removable elastomer

- Standard L type coupling with snap wrap elastomer

- Higher RPM limit of 3600 RPM

- Max. bore- 2.625 inches (65 mm)

- RRS/RRSC type- Radially removable spacer coupling

- Center drop out to avoid proper shaft separation

- Spacer is made of glass reinforced plastic, cast iron, or aluminum

- Max. bore-1.875 inches (48 mm)

- Max. torque-3708 in-lbs (419 Nm)

- RRC type- radially removable spacer coupling

- Large version of RRS/RRSC type coupling

- Radially removable spacer makes installation easy

- C type- Higher type jaw coupling

- Greater bore and torque capacity

- Max. bore-4.000 inches (102 mm)

- Max. torque- 37800 in-lbs(4271 Nm)

- H type- Highest torque jaw coupling

- Highest bore and torque capacity

- Max. bore-7000 inches (178 mm)

- Max. torque-170000 in-lbs (19209 Nm)

S-Flex endurance coupling

- The S–Flex Endurance coupling design is comprised of three parts. Two flanges with internal teeth engage an elastomeric flexible sleeve with external teeth.

- Easy to install

- No lubrication

- Double engagement

- Dampens vibration and control shock

- Thirteen sizes are available with torque capabilities that range from 60 in-lbs (6.78 Nm) to 72,480 in-lbs (8189 Nm).

Torsional couplings

- LF series

- The LF Series coupling is designed with a unique and highly versatile elastomeric element.

- Family of couplings designed specifically to address problematic torsional vibration

- LVK series

- The LVK Series is designed for direct coupled equipment.

- Element bonded to flywheel mounting plate and LK style hub housing

- Available in high temp rubber (HTR) or EPDM

- Nominal torque: up to 5,800 in-lb (655 Nm)

- LV series

- The LV Series coupling is designed and built for diesel engine driven equipment

- Economical alternative for agricultural & off-highway industrial equipment

- Available in high temp rubber (HTR) or EPDM

- Nominal torque: up to 10,820 in-lb (1223 Nm)

- LM series

- Designed for mounting on standard SAE J620 flywheels

- Available in high temp rubber (HTR), EPDM, or Silicone

- Nominal torque: up to 33,600 in-lb (3800 Nm)

- LK series

- Simple two-piece design for low-mid power diesel driven hydraulic systems

- Composed of flywheel mounted element & star shaped hub

- Nominal torque: up to 21,240 in-lb (2400 Nm)

Sizes & Selection

- Basic information that is required for the selection of coupling is

- Power of the driver (HP or KW)

- RPM (at the point of the coupling)

- Shaft and keyway sizes

- Shaft separation or BSE (between shaft ends)

- Type of driven equipment (i.e pump, compressor, etc.)

- For the detailed selection of coupling please refer to the attached catalog.

Applications

- Internal combustion power transmission

- Electric motor

- Power transmission to industrial equipment

- Earthmoving equipmentt

- Diesel engine driven equipment