Instructions to Page Editor Source from – \Google Drive\M Drive\Common Document Center\Technical Details\Brands\REXNORD\Products\Couplings

About Coupling (Sub-brand of Rexnord)

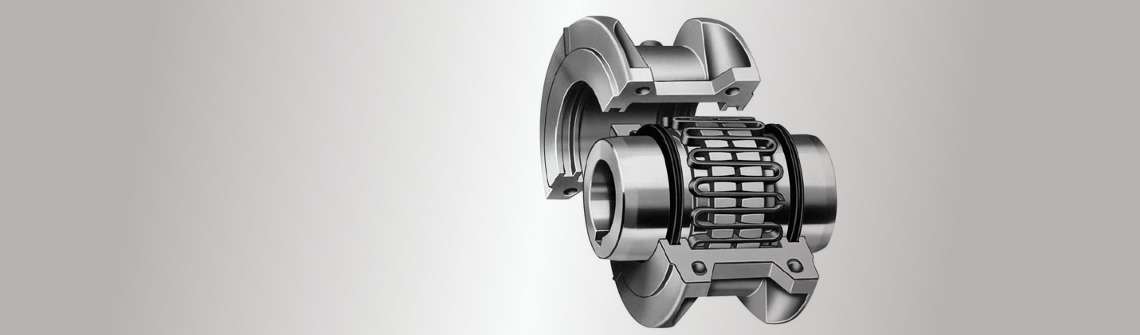

Grid couplings are common in a variety of industries and applications because they are able to operate under extreme conditions and handle high levels of torque. There are several brands of grid couplings and they all appear to be identical. However, third party tests discussed in this paper show a wide range of results measuring the performance and durability of Falk, Dodge, and Lovejoy branded grid couplings. These results demonstrate that there can be a significant impact on the uptime and production on your system, plant or mine by the brand of grid coupling that is specified.

Installation procedure

Design Attributes & Advantages

- The unique “replace in place” design eliminates the need to move hubs or realign shafts, reducing element change-out time.

- High Strength alloy steel taper grid member are quenched and tempered to spring hardness. The grid surface is shot peened resulting in dramatic increase of Fatigue strength and torque ratings.

- Steelflex tunes the drive system. It absorbs impact energy by spreading it over an increment of time. It damps vibration and reduces peak or shock loads by as Much as 30%.

- Durable Nitrile Seals are heat resistant to 275°F (135°C).

- Pipe plugs with Steel Material Zinc Plated Finish to ensure an adequate grease reservoir during initial start-up and application run.

T10 Series

- Horizontal Split Cover

- General Purpose Design

- Easy access to grid

- Lowest Initial cost

T20 Series

- Vertical Split Cover

- General Purpose Design

- Ideal for Higher operating speeds

T31 Series

- Full Spacer Design.

- Suited for Pump Applications.

- Drop Out spacer midsection allows space to service pump seals and bearings.

T35 Series

- Half Spacer Design

- Use when full length spacer is not required.

- Less costly than the T31

T50 Series

- Used on Floating Shaft Assemblies for Long Distance between Shaft Ends.

- Can also be used in place of single engagement gear couplings

T70 Series

- High Speed Design

- For speeds well beyond the range of the basic T10/T20 Coupling.

- Features a One piece cover and balanced components.

Sizes & Selection / Nomenclature

Standard Selection Method

The standard selection method can be used for most motor, turbine or engine-driven applications. The following information is required to select a flexible coupling:

- Horsepower or torque

- Running rpm

- Application or type of equipment to be connected (motor to pump, gear drive to conveyor, etc

- Shaft diameters

- Shaft gaps

- Physical space limitations

- Special bore or finish information and type of fit

Applications

- Cement

- Petro-chemical and Refining

- Pulp and Paper Mills

- Steel

- Aluminium

- Power Utilities

- Aggregate Processing

- Lumber

For more details go through the catalog