Page marked as complete for v1.0

About

Tollok is now part of Rexnord. Tollok manufactures highly engineered shaft locking devices for the power generation and process industries, as well as general industrial applications. These products are used to secure rotating shafts, manage torque transmission, and counteract shaft bending and vibration. With more than 40 years of application experience, the company’s product technology and expertise help customers manage process variability and maximize uptime.

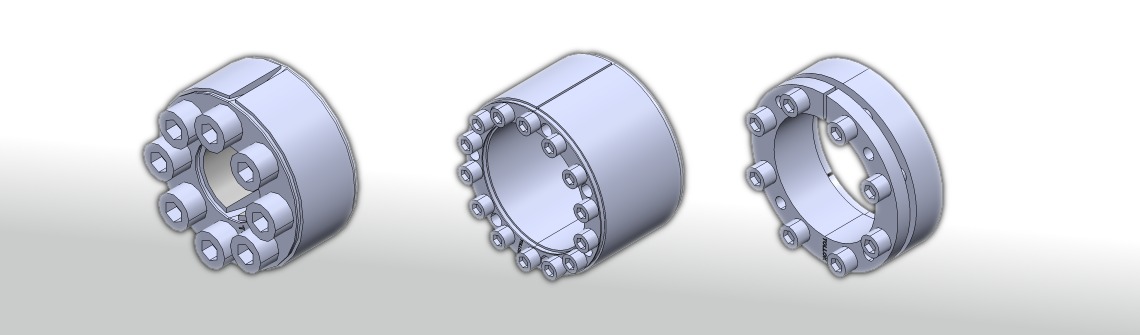

Rexnord Tollok Locking Assemblies are a great alternative to a shaft/hub connection such as key, splined, press fit, QD bushing, or taper-lock bushings. Customers count on Rexnord Tollok Locking Assemblies to reduce maintenance costs and downtime, increase productivity, provide customized configurations, and more, no matter what the application.

Basic Information

Multiple configurations and custom designs– For your specific needs, our experienced engineers offer multiple configuration options and customized designs with dimensionally tight tolerances to optimize performance and extend service life in critical applications.

Application and design engineering technical expertise- Trusted expertise to support and guide you in solving your application challenges. Provide options to meet customer specific application requirements and provide engineering models for full integration into your designs.

Design Attributes & Advantages

Rexnord Tollok Locking Assemblies are available in 1/4- to 35-inch (6 to 900 millimeters) configurations, such as internal self-centering

and external locking hub mounts. Each configuration has unique features ideal for specific applications

Sizes & Selection / Nomenclature

TLK132 & TLK133 internal locking device

- Minimal screw design utilizes larger diameter screws on smaller profiles

- Improved radial capacity to support mounted component on equipment under load

- Self-centering design reduces installation time and ensures alignment with connected equipment

- Axial movement option allows proper device selection

- 3/4- to 8-inch (20 to 200 mm) internal diameter range

- Popular choice for connections to equipment shafts

TLK450 & TLK452 internal locking device

- 701 to 518,000 ft-lbs (950 to 702,314 Nm) torque capacity

- Compact size for specific applications

- Self-centering design reduces installation time and ensures alignment with connected equipment

- Handle bending moments from equipment application designs

- 1- to 8-inch (25 to 200 millimeters) internal diameter range

- Popular choice for bulk handling, conveying and industrial applications with multiple loads

TLK600 series external locking device

- 22 to 966,204 ft-lbs (30 to 1,309,997 Nm) torque capacity

- Lack of shaft to hub axial movement eliminates fretting corrosion and hub failure

- Low inertia reduces rotating design impact in system designs

- Quick assembly and disassembly reduces installation and downtime

- 1/2- to 19- inch (14 to 480 millimeters) internal diameter range

- Popular choice for shaft mounting reducer, hollow shaft mount, shaft couplings, and wind energy applicatio

Applications